Self Fluxing Alloy ak mete ak korozyon reziste

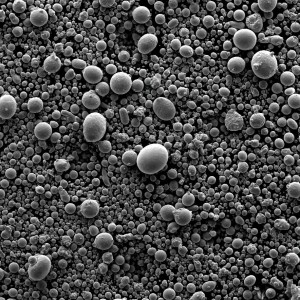

Deskripsyon

NiCrBSi seri alyaj poud ak dite segondè se pi lajman itilize usure rezistan ak korozyon alyaj poud ki ba pwen k ap fonn ak tanperati k ap fonn poud.Li gen ekselan fuzibilite pwòp tèt ou, mouillabilite ak pèfòmans soude espre.Li se souvan itilize pou korozyon reziste ak mete rezistan, espesyalman pou pwoteksyon an prevantif ak reparasyon nan glisman pati ki reziste mete.

Pwodwi menm jan an

| Mak | Non pwodwi | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-Ni15 | NiCrBSiFe | |||||

| KF-Ni25 | NiCrBSiFe | |||||

| KF-Ni35 | NiCrBSiFe | 12 | NI563 | 65 | ||

| KF-Ni45 | NiCrBSiFe | 14 | 69 | |||

| KF-Ni55 | NiCrBSiFe | |||||

| KF-Ni60B | NiCrBSiFe | |||||

| KF-Ni60A | NiCrBSiFe | 335 | 15/2001 | NI167 / 1275 | 60 | |

| KF-Ni60AA | NiCrBSiFe | 335 | 15/2001 | NI167 / 1275 | 60 | |

| KF-300A | Ni60+35WC-Ni | 36 / 734 | WC562 | 81 | ||

| KF-300B | Ni60A+50WC-Co | 34 / 734 | WC487 | 89 | ||

| KF-300C | Ni60+35WC-Co | |||||

| KF-300D | Self-fluxing Nikel baz Tugsten Carbide |

Spesifikasyon

| Mak | Non pwodwi | Chimi (wt%) | Dite | Tanperati | Pwopriyete ak aplikasyon | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | B | Ni | |||||

| KF-Ni15 | NiCrBSiFe | 0.15 | 5 | 2 | 5 | 1 | Bal. | HRC 15 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Glas moule, bi •Low dite, segondè severite •Good kowozyon rezistans ak wetability |

| KF-Ni25 | NiCrBSiFe | 0.20 | 7 | 2.8 | 5 | 1.5 | Bal. | HRC25 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Glas moule, bi •Low dite, segondè severite •Good oksidasyon ak korozyon rezistans kòm byen ke mouye •Exellent machinability |

| KF-Ni35 | NiCrBSiFe | 0.30 | 9 | 3 | 5 | 2 | Bal. | HRC 35 | ≤ 650ºC | •Glas moule, bi •Pistons •Syèj valv |

| KF-Ni45 | NiCrBSiFe | 0.45 | 13 | 3 | 10 | 2.5 | Bal. | HRC45 | ≤ 650ºC | •Glas moule, bi •Pistons •Syèj valv |

| KF-Ni55 | NiCrBSiFe | 0.75 | 15 | 3 | 10 | 3 | Bal. | HRC 55 | ≤ 650ºC | • Mwazi •BEARINGS •Pistons |

| KF-Ni60B | NiCrBSiFe | 0.80 | 17 | 4 | 15 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Lam fanatik yo •Boiler tib •Pistons |

| KF-Ni60A | NiCrBSiFe | 0.80 | 17 | 4 | 5 | 3.5 | Bal. | HRC 60 | ≤ 650ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Pistons, transport woulèt, fil fè desen rale wou, extrusion plimen •High dureté, usure ak kowozyon rezistans |

| KF-Ni60AA | NiCrBSiFe | 0.90 | 17 | 5 | 3 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Oil couplage • Conveyor roulo •Desen fil rale wou, •Extrusion vis |

| KF-300A | Ni60A+35WC-Ni | Ni60A+35WC-Ni | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Wire desen rale wou, lam, piston, impeller •Pi bon rezistans mete pase Ni60 | |||||

| KF-300B | Ni60A+50WC-Co | Ni60A+50WC-Co | HRC65 | ≤ 600ºC | •Brik machin •Ajitasyon sediman •Extrusion vis •Ekipman agrikòl | |||||

| KF-300C | Ni60A+30WC-Co | Ni60A+30WC-Co | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Wire desen rale wou, lam, piston, impeller •Pi bon rezistans mete pase Ni60 •Exellent patikil ak difisil fè fas a fwotman ak rezistans erosion | |||||

| KF-300D | Self-fluxing Nikel baz Tugsten Carbide | Pwopriyetè | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, lazè CLADDING, self-fluxing, esferik •Wire desen rale wou, lam, piston, impeller •Pi bon rezistans mete pase Ni60 •Self-fluxing •Exellent patikil fwotman ak rezistans korozyon | |||||